Machinery Safety

→ System design aligned with EU machinery safety requirements.

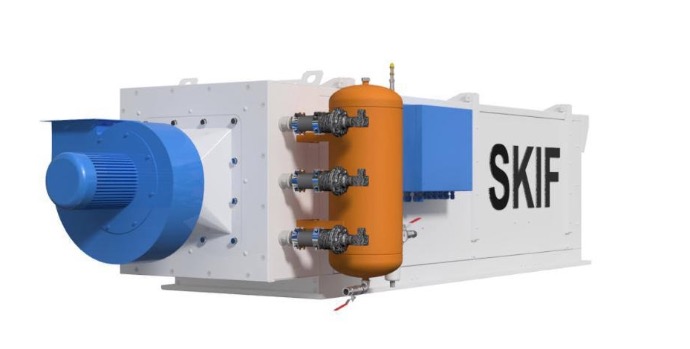

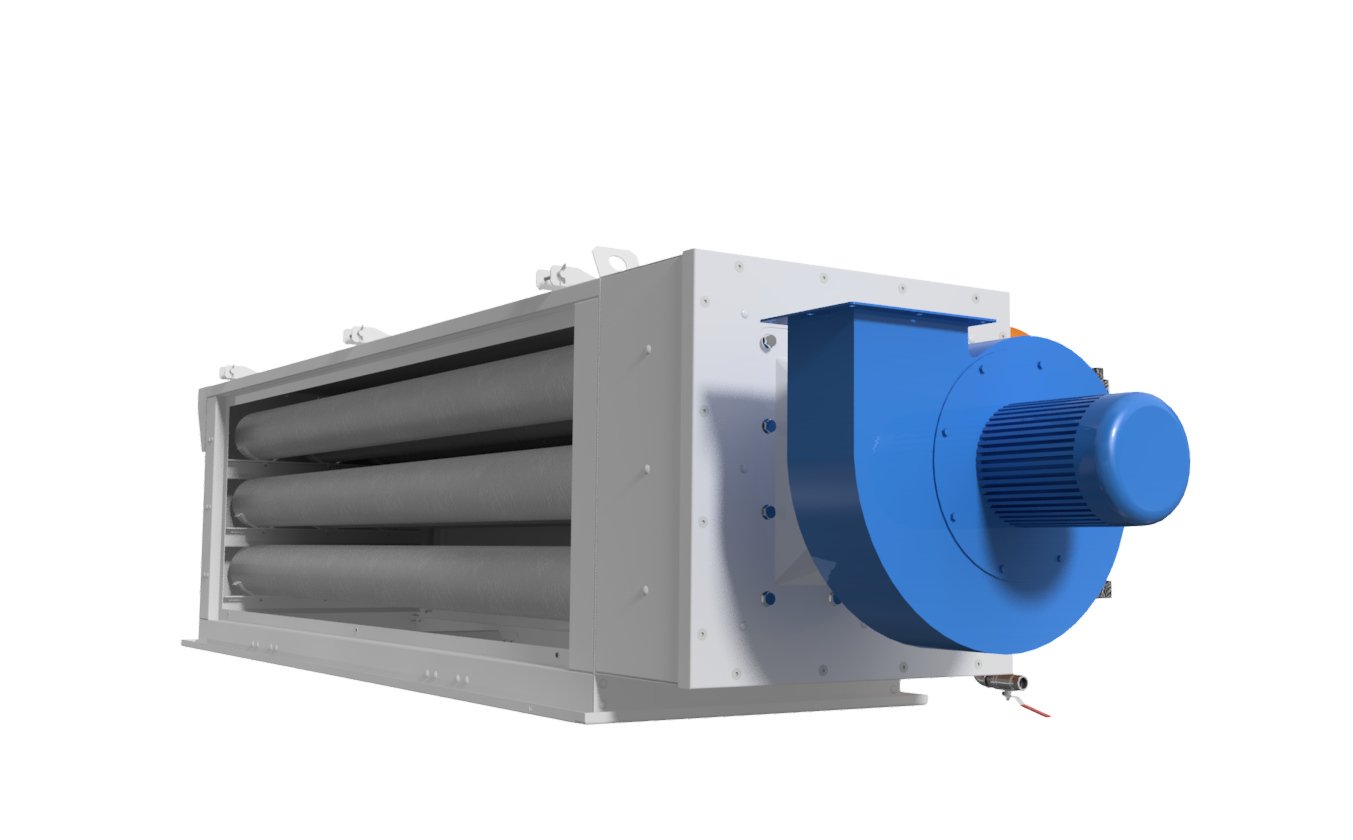

Uni-f ™ is an industrial bag filtration system designed for efficient dust capture directly at the point of generation.

The system is engineered for processes with high dust loads and unstable operating conditions, where reliable filtration, process safety, and emission control are critical.

The filtration concept ensures full return of captured dust back into the technological process, eliminating product losses while maintaining optimized energy consumption.

Uni-f ™ meets the requirements of IED 2.0 and is suitable for use in potentially explosive zones.

Machinery Directive 2006/42/EC

→ System design aligned with EU machinery safety requirements.

Low Voltage Directive 2014/35/EU

→ Safe operation of electrical components in industrial environments.

EN ISO 13849

→ Reliable control and safety-related system functions.

ATEX Directive 2014/34/EU

→ Suitable for potentially explosive atmospheres.

Active & passive explosion protection options

→ Configurable safety concepts depending on process risk.

IED 2.0 — Directive (EU) 2024/1785

→ Emission levels compliant with current EU regulations.

Machinery Directive 2006/42/EC

→ System design aligned with EU machinery safety requirements.

Low Voltage Directive 2014/35/EU

→ Safe operation of electrical components in industrial environments.

EN ISO 13849

→ Reliable control and safety-related system functions.

ATEX Directive 2014/34/EU

→ Suitable for potentially explosive atmospheres.

Active & passive explosion protection options

→ Configurable safety concepts depending on process risk.

IED 2.0 — Directive (EU) 2024/1785

→ Emission levels compliant with current EU regulations.

Key advantages:

Captured dust is fully returned to the process, ensuring preservation of product mass

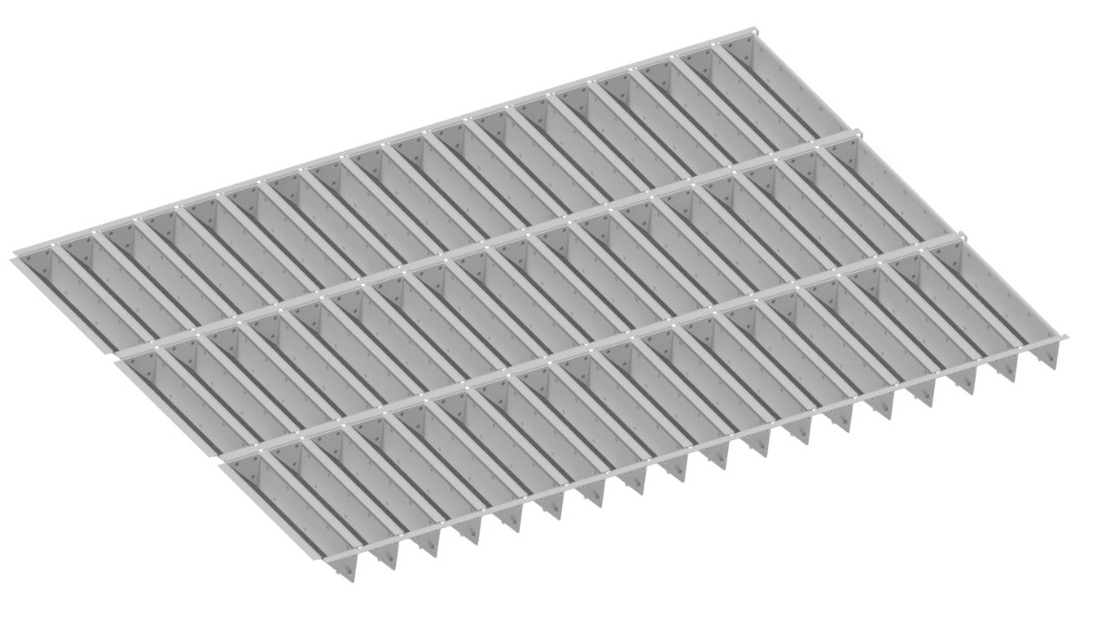

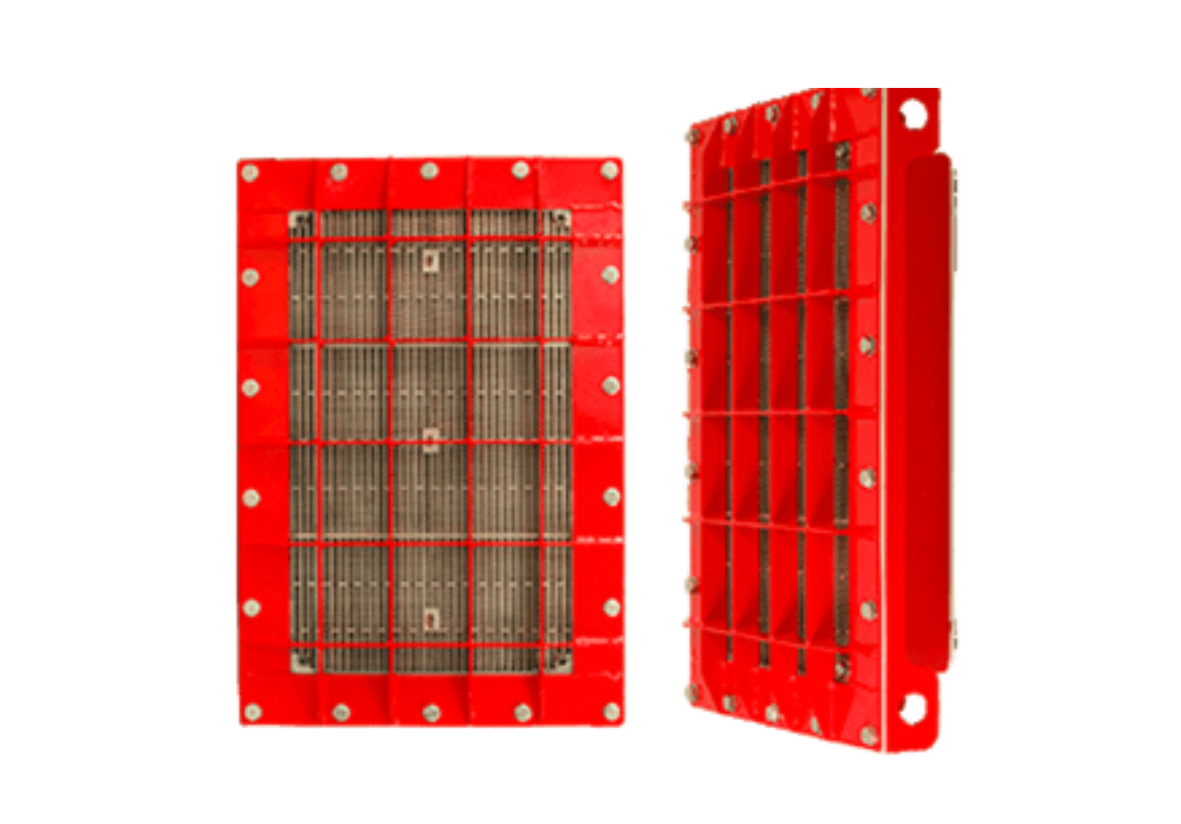

Application of a unique hybrid filtration technology

Filtration directly at the point of dust generation ensures maximum system efficiency

Optimized energy consumption compared to аналогs, achieved through optimal filtration velocity and specialized filter media

High dust load • Continuous process

Controlled emissions • Clean production

Process safety • Dust containment

Explosive dust risk • High throughput

Harsh conditions • Compliance driven

Very high dust • Heavy duty operation

High dust load • Continuous process

Controlled emissions • Clean production

Process safety • Dust containment

Explosive dust risk • High throughput

Harsh conditions • Compliance driven

Very high dust • Heavy duty operation

| Model of the filter | Performance, m³/h |

Filter area, m² |

A | B | C | D | E | F | ØG | H | I | Weight without rotor, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Uni-f-6 | 500–1000 | 3,5 | 1855 | 1030 | 730 | - | - | 200 | 580 | 415 | 160 | |

| 1920 | 543 | 1030 | 585 | 1570 | 590 | |||||||

| Uni-f-9 | 1000–1700 | 6,7 | 2260 | 1100 | 945 | - | - | 230 | 585 | 585 | 215 | |

| 2320 | 715 | 1020 | 755 | 1970 | 590 | |||||||

| Uni-f-12 | 1700–3250 | 11,3 | 2755 | 1270 | 945 | - | - | 255 | 755 | 585 | 280 | |

| 2755 | 715 | 1270 | 755 | 2455 | 760 | |||||||

| Uni-f-20 | 3250–5000 | 18,9 | 3020 | 2765 | 1240 | 835 | 310 | 310 | - | 930 | 755 | 385 |

| 2930 | 885 | 1215 | 1130 | 2435 | 930 | |||||||

| Uni-f-28 | 5000–7000 | 26,4 | 2995 | 2895 | 1490 | 1150 | 400 | 400 | - | 1270 | 755 | 480 |

| 2930 | 885 | 1560 | 1130 | 2435 | 1270 | |||||||

| Uni-f-40 | 7000–10000 | 37,7 | 2895 | 2895 | 2000 | 1090 | 600 | 600 | - | 1780 | 755 | 645 |

| 2915 | 1490 | 1130 | 2435 | 1780 | ||||||||

| Model of the filter | Performance, m³/h |

Filter area, m² |

A | B | C | D | E | F | ØG | H | I | Weight without rotor, kg |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Uni-f-6 | 500–1000 | 3,5 | 1855 | 1030 | 730 | - | - | 200 | 580 | 415 | 160 | |

| 1920 | 543 | 1030 | 585 | 1570 | 590 | |||||||

| Uni-f-9 | 1000–1700 | 6,7 | 2260 | 1100 | 945 | - | - | 230 | 585 | 585 | 215 | |

| 2320 | 715 | 1020 | 755 | 1970 | 590 | |||||||

| Uni-f-12 | 1700–3250 | 11,3 | 2755 | 1270 | 945 | - | - | 255 | 755 | 585 | 280 | |

| 2755 | 715 | 1270 | 755 | 2455 | 760 | |||||||

| Uni-f-20 | 3250–5000 | 18,9 | 3020 | 2765 | 1240 | 835 | 310 | 310 | - | 930 | 755 | 385 |

| 2930 | 885 | 1215 | 1130 | 2435 | 930 | |||||||

| Uni-f-28 | 5000–7000 | 26,4 | 2995 | 2895 | 1490 | 1150 | 400 | 400 | - | 1270 | 755 | 480 |

| 2930 | 885 | 1560 | 1130 | 2435 | 1270 | |||||||

| Uni-f-40 | 7000–10000 | 37,7 | 2895 | 2895 | 2000 | 1090 | 600 | 600 | - | 1780 | 755 | 645 |

| 2915 | 1490 | 1130 | 2435 | 1780 | ||||||||

Start with the customer – find out what they want and give it to them.